Multi Confectioner

Warning: Undefined variable $post in /home/kibidango/kibidan-go.co.jp/public_html/rheon-japan.kibidan-go.co.jp/wp-content/themes/rheon-child/blocks/lazyblock-custom-tax-list/block.php on line 8

- Encrusting Machine

- Multi-row model

Warning: Undefined variable $post in /home/kibidango/kibidan-go.co.jp/public_html/rheon-japan.kibidan-go.co.jp/wp-content/themes/rheon-child/blocks/lazyblock-custom-tax-list/block.php on line 28

Warning: Attempt to read property “ID” on null in /home/kibidango/kibidan-go.co.jp/public_html/rheon-japan.kibidan-go.co.jp/wp-content/themes/rheon-child/blocks/lazyblock-custom-tax-list/block.php on line 28

Compact & High performance multi-row encrusting machine for confectionery. Maximum 115,200 pcs./h (MX110-WD100, 16 rows model) , Maximum 144,000 pcs./h (MX112-WD1200, 20 rows model) Product Weight Range is 10 – 25g.

Features

Video

Compact & High performance

Equipped with newly developed “no-damage material transmittal system” and “encruster” in this compact body of less than 2 meters. Furthermore, the distance of the material is minimal so it maintains the natural texture of the product. Casing and filling ratio is freely adjustable and the product weight is easily regulated in keeping the same ratios.

Wide variety of shapes can be made with many options

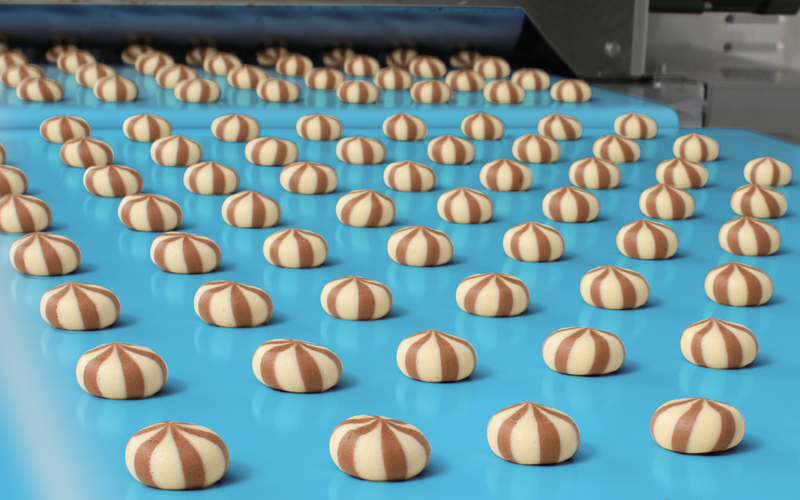

Wire Cutter Unit (+ Mosaic nozzle)

The Wire cutter slices the co-extruded cookie dough to a desired thickness. Limitless designs of mosaic nozzles increase the variety of cookies.

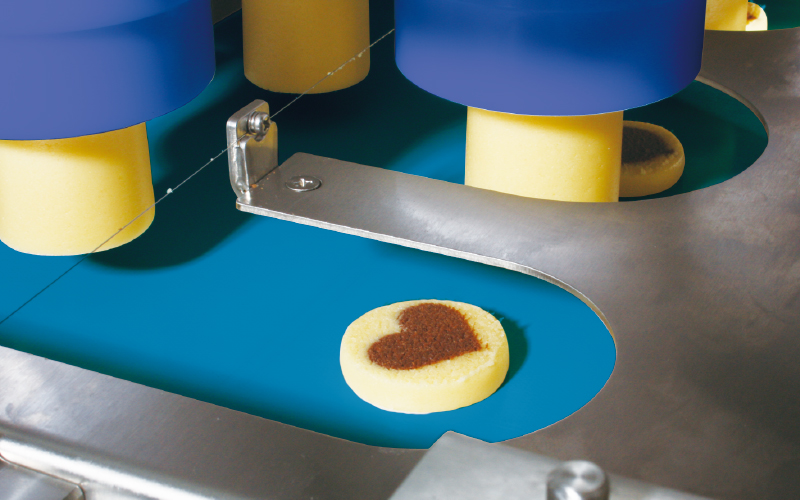

Double Filling Feeder

The Double Filling Feeder supplies pastry filling such as cream and jam into filled products, creating double filling products. The option is mounted on the body of the machine with no extra space required. Uniquely shaped products can be made with custom nozzles.

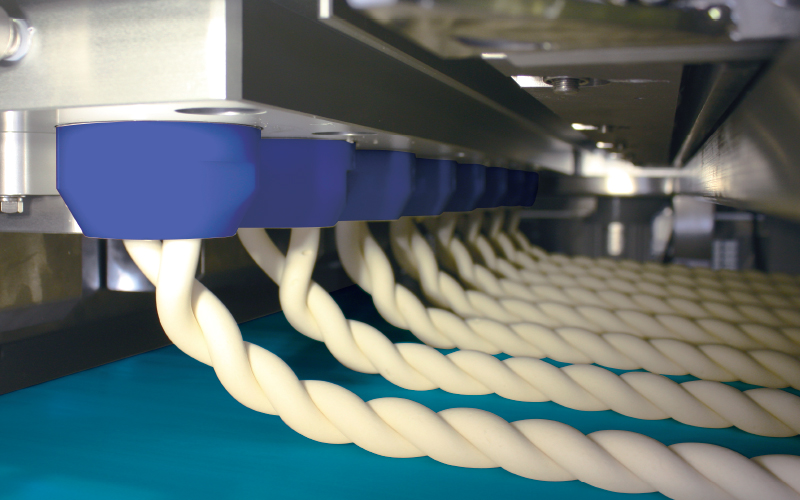

Twist Nozzle (+ Vertical Cross Cutter)

The Twist Nozzle and Vertical Cross Cutter co-extruders two lines of dough with different fillings and produces twist products.

* Number of production row reduces by half.