Concha Production Line

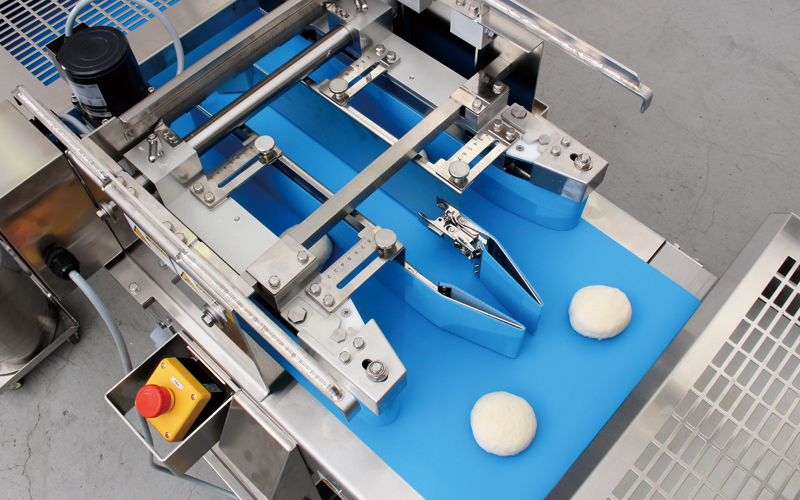

Molding Device

Positions the dough ball as it continues to shape.

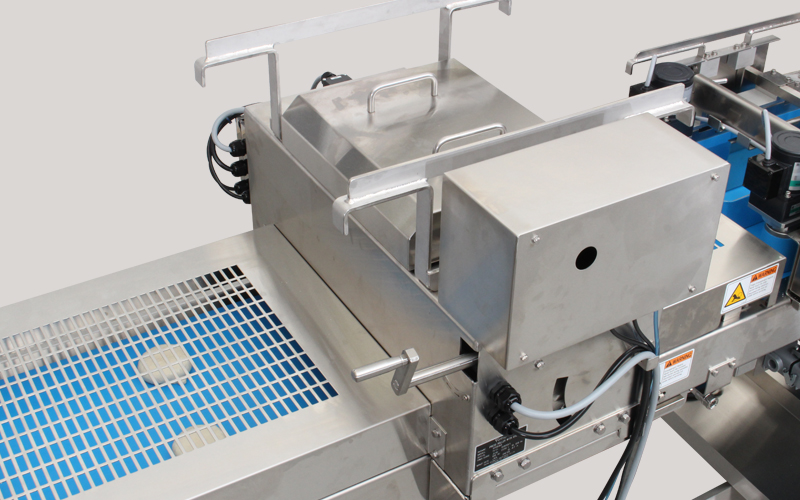

Press Roller with Oil Spray

Cookie Dough Depositor

Round “pasta” is deposited and positioned on the dough ball.

Press Roller with Flour Duster

Press the surface lightly as it dusts with flour.

Stamping Divice 2 Rows

Stamps the “pasta” accurately to conclude process.

Product image

Features

Video

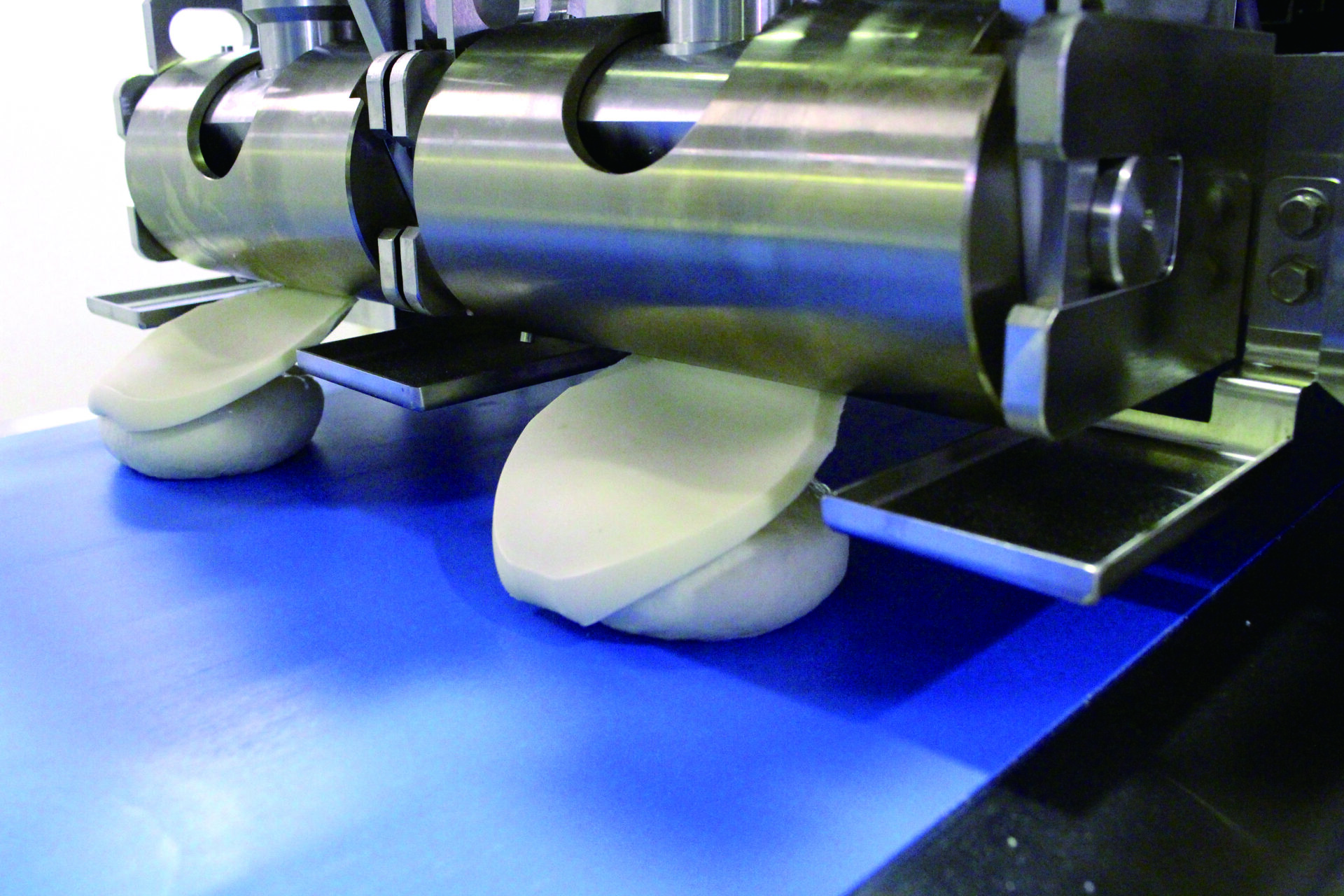

What’s Concha

Concha is a traditional Mexican confection. Cookie dough called “Pasta” is layered over sweet bread dough, then formed into a seashell and baked. Shops display varicolored rows of yellow, white, and pink Conchas, and the local people love to eat them.

User-friendly Operation

Each row is independently position-controlled using sensors. The sensors precisely detect the flow of the dough, which is covered at the optimum position for each row and then formed using the stamper.